What Full-Service Means at Tru-Form

We manage every phase of the custom thermoforming process in-house:

- Engineering collaboration to refine form, material, and manufacturability

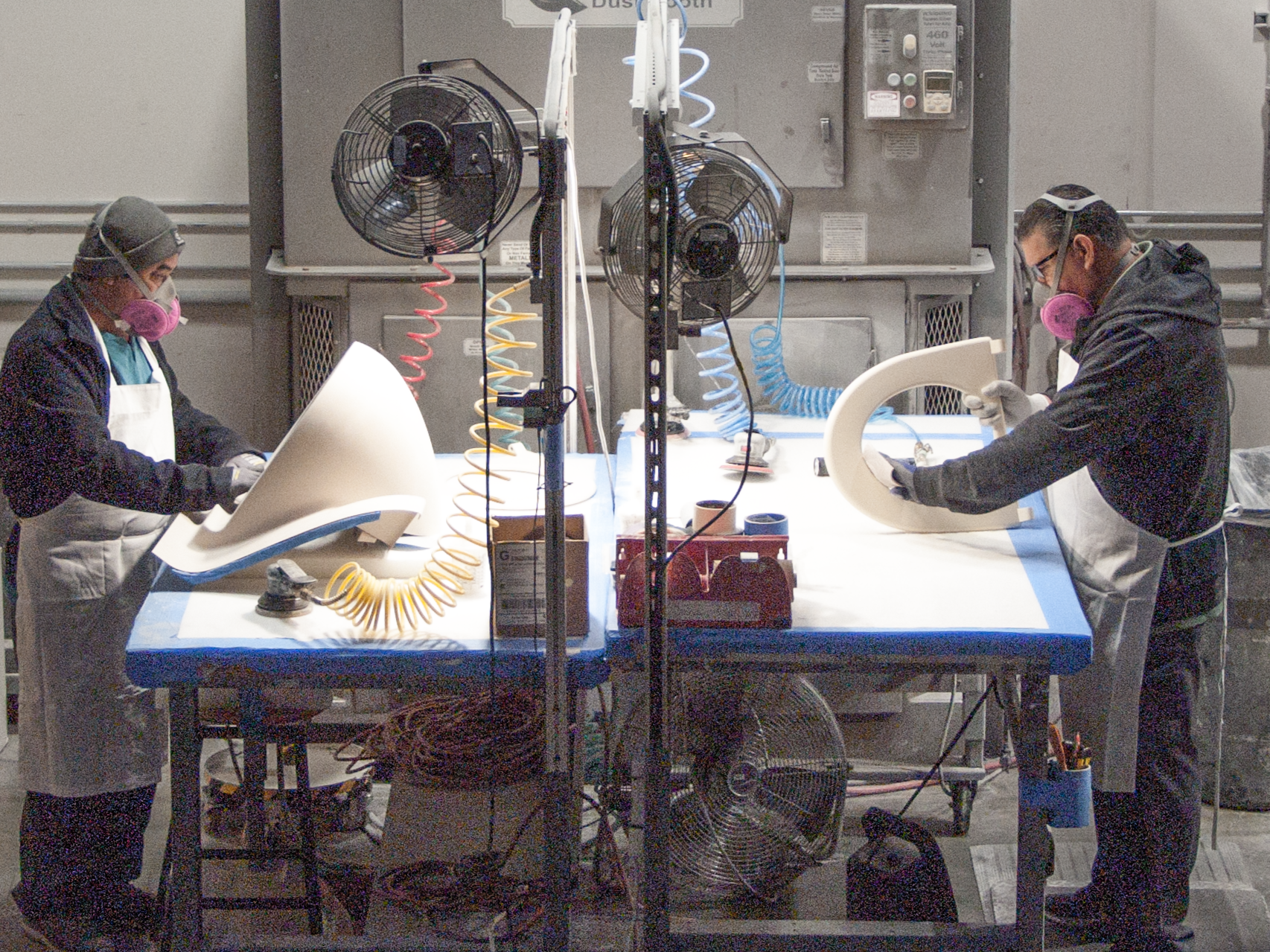

- In-house tooling and trimming fixture development

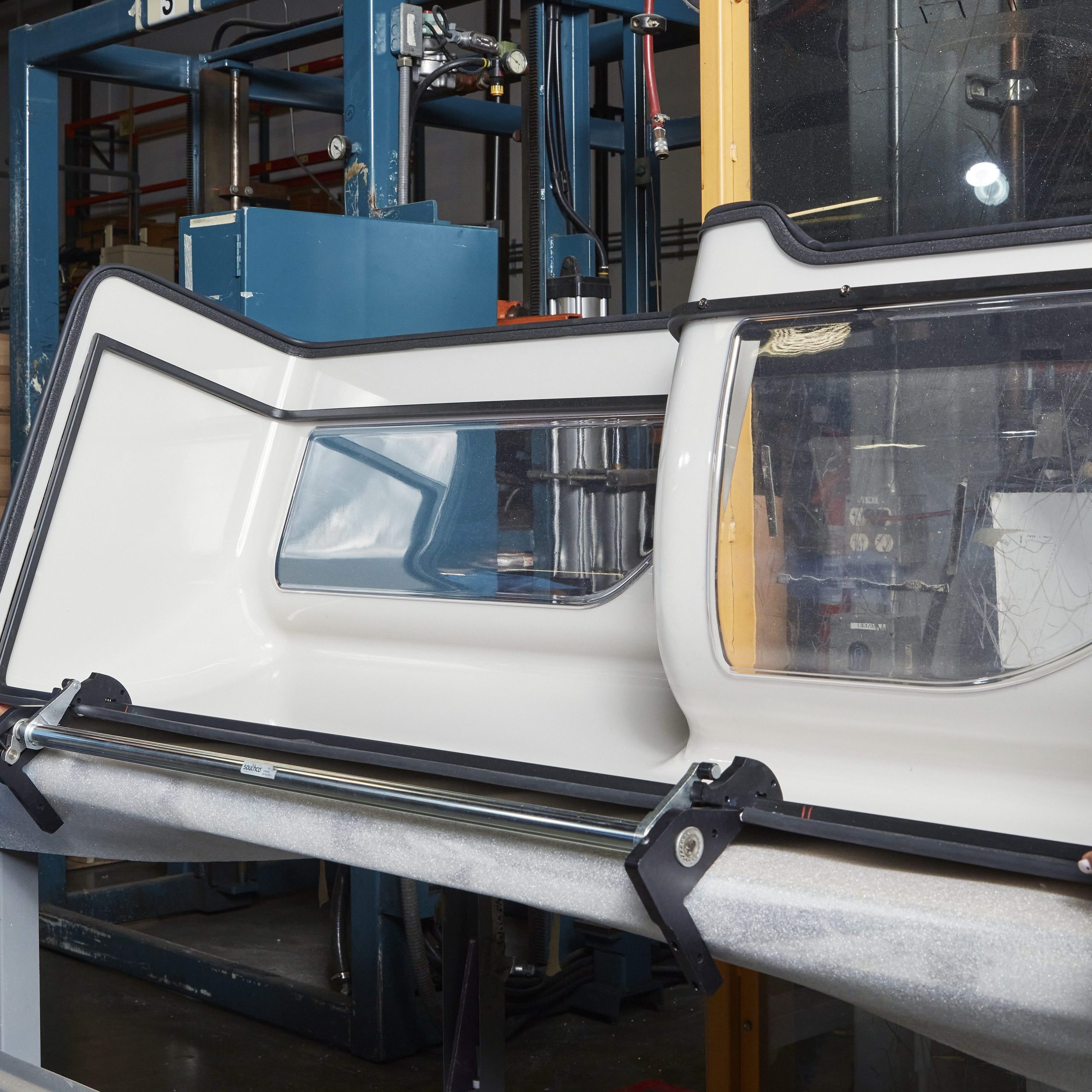

- Heavy gauge thermoforming and thin gauge thermoforming using both vacuum forming and pressure forming processes

- Assembly and fabrication for parts that require hardware, adhesives, fasteners, or EMI shielding

- Packaging and fulfillment to meet cleanroom or transport specifications

Built to Support Your Entire Build

- Quantities from short runs to millions of units

- Part sizes up to 5’x9′ with draw depths to 28″

- Material expertise across PETG, LDPE, HDPE, PP, PC/ABS, PS, PVC, Ultem™, Kydex®, and Boltaron®

- Certified to AS9100 and ISO 9001:2015 quality standards

We support regulated industries that demand consistency, documentation, and precision at every step. Our team takes ownership of each phase, from initial concept input to forming, trimming, bonding, and shipment.

Explore how full-service plastic thermoforming can streamline your production process.