Aerospace

Aerospace clients depend on us for quick turnaround time and volume scalability for airline interiors, seating, cabins, lavatories, cockpits, and more.

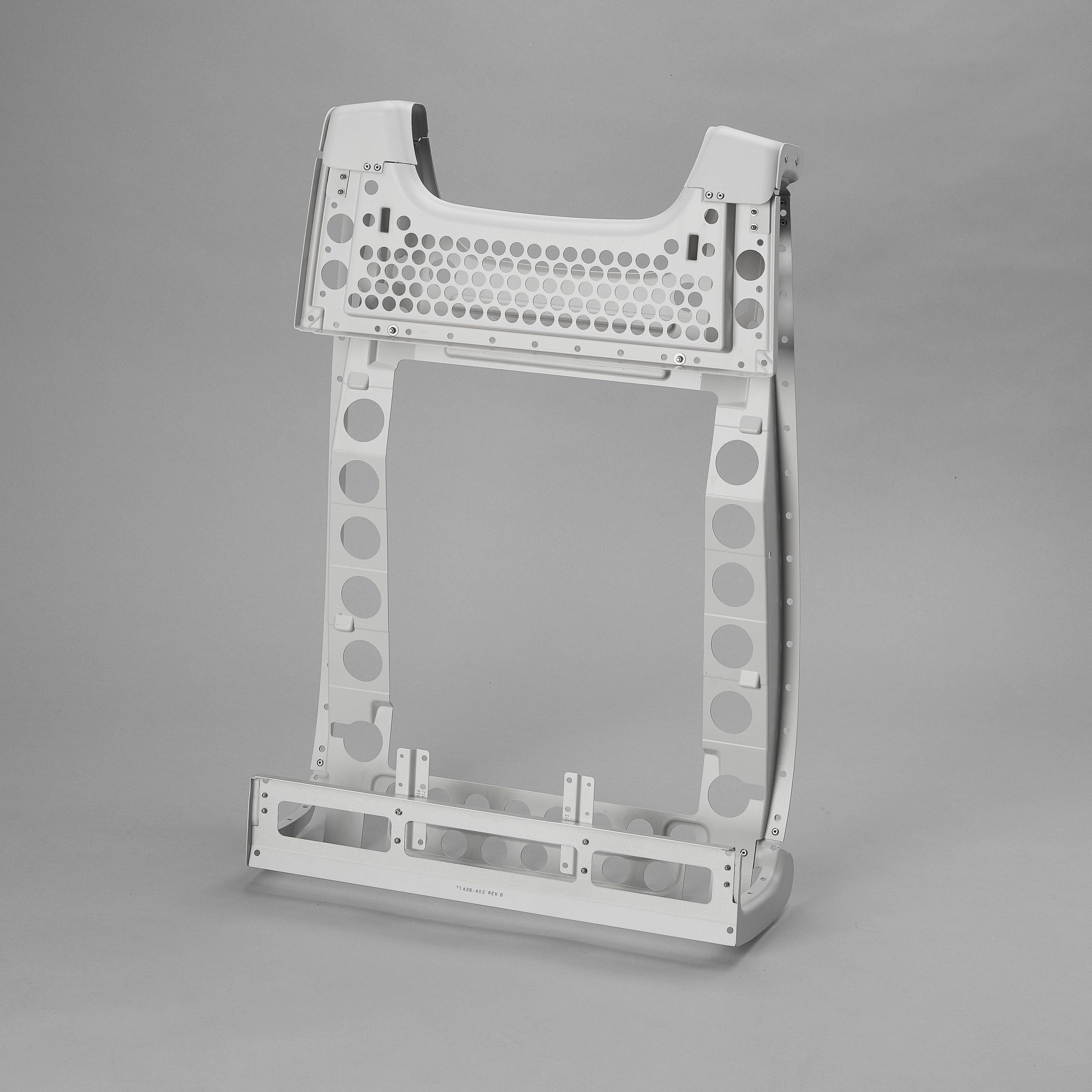

Our customers rely on us to build lightweight, compliant parts that maintain strength and durability.

Aerospace Plastics & Interiors

AIRCRAFT INTERIORS

Vacuum formed components have become more common in aviation and the aerospace industries for many reasons, including weight reduction, ease of prototyping, low-cost tooling, design freedom, quick turnaround time, and volume (small to large production runs).

In the aviation/aerospace industries, vacuum forming has many common applications (including) aircraft interior paneling, gallery components, overhead luggage bins, seating parts, window shades, light housings, and ducting.

AEROSPACE PLASTICS

Seat Backs, Tray Tables, Gallies & Lavatories.

Aircraft seating components made from thermoformed plastics offer light weight, outstanding cosmetic appeal, are colored through, and are fully FAR 25.853 25.853 flame retardant. The process is ideal for the low volumes and specialized, ever changing designs of the aircraft interior business. We have considerable experience with both vacuum and pressure formed seating components, and we are considered a world class supplier by the largest players in this industry. We deliver quality, but also the ability to manage the complex logistics and short lead-times that characterize this industry.