Engineered for Performance

We understand the demands of regulated industries and specialize in thermoforming for medical devices, thermoforming for aerospace components, and thermoforming for automotive parts and electronics housings. Our engineering process focuses on:

- Reducing validation delays

- Supporting cleanroom plastic forming and sterile packaging requirements

- Matching materials to end-use needs

- Designing for repeatability and regulatory compliance

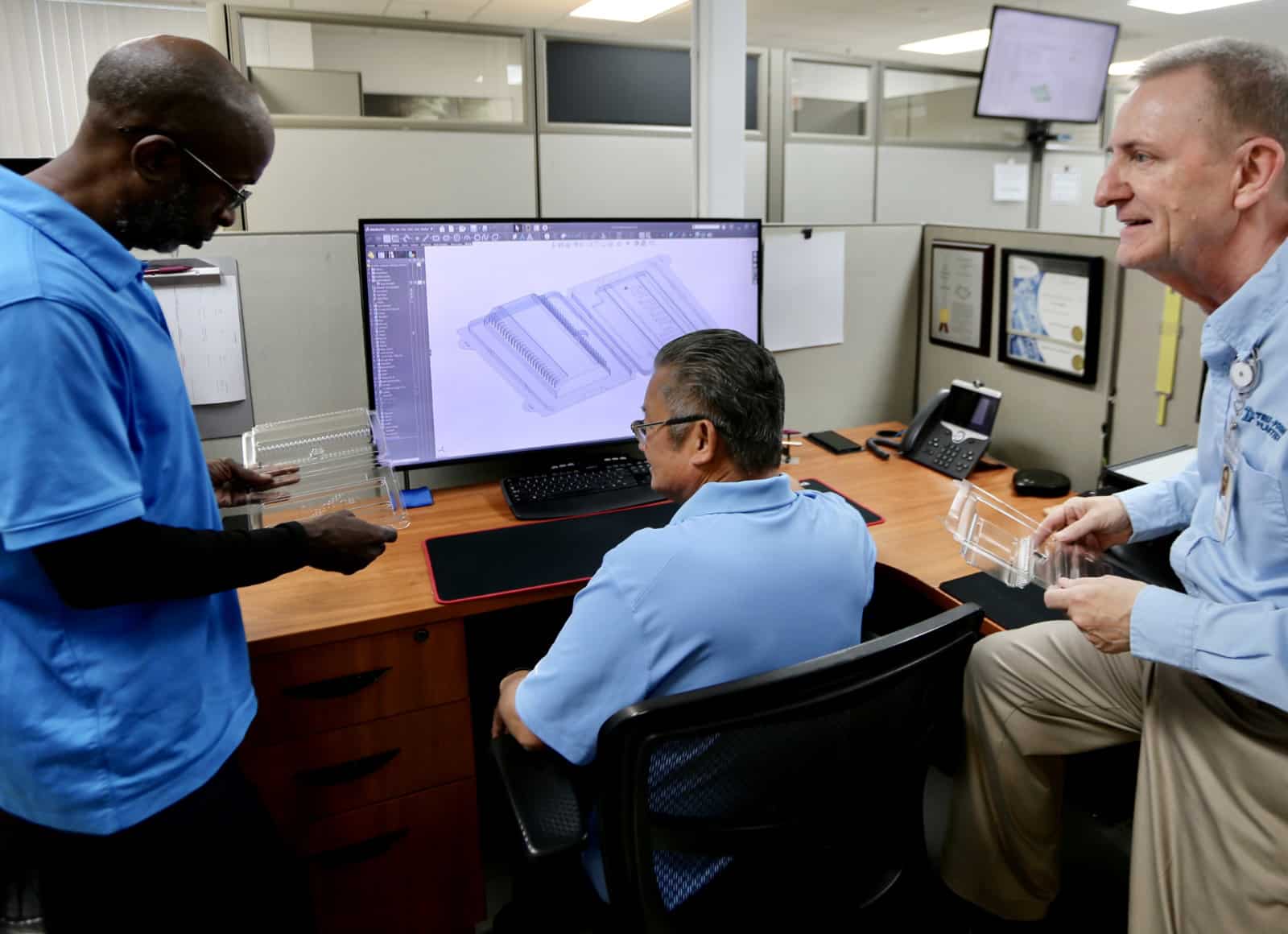

Precision Custom Thermoforming Support

When your application requires tight specs, detailed part geometry, or validated production, our engineering team delivers. We combine experience with practical insights to make the tooling and forming process more efficient and reliable.

We also support advanced forming approaches like:

- Pressure forming for higher detail and definition

- Vacuum forming for durable, large-format parts

- Integrated fixturing and tooling for complex assemblies