Aerospace

Lightweight, Compliant Components for Complex Aerospace Builds

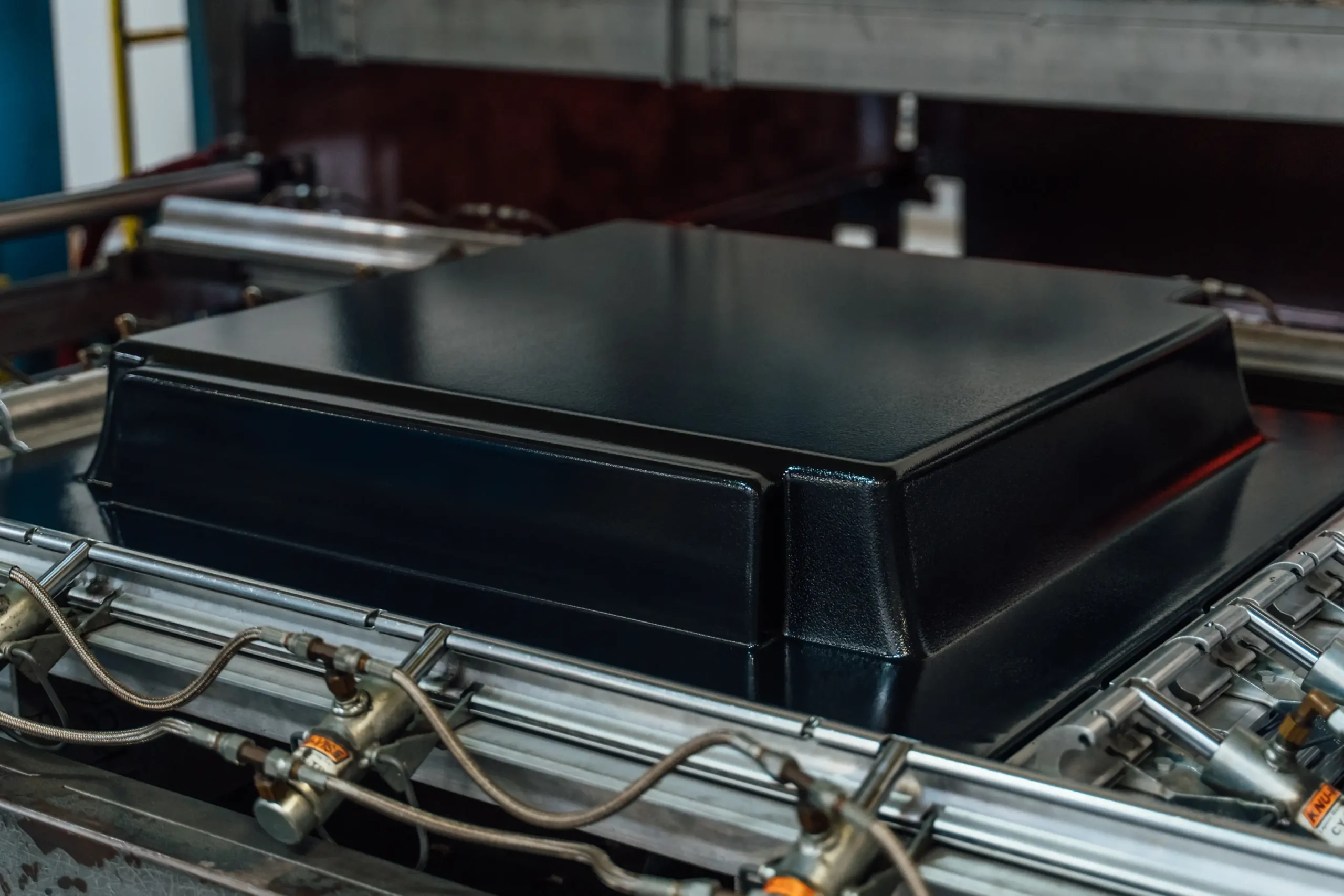

Tru-Form Plastics provides aerospace packaging thermoforming solutions for OEMs, Tier 1 suppliers, and cabin interior specialists. We produce lightweight, flame-rated components using vacuum forming and heavy gauge thermoforming methods tailored to aerospace performance standards.

From seating and panel systems to shrouds and housings, we support short runs, legacy replacements, and scalable production with repeatable quality.

Proven in Flight

As a trusted aerospace thermoformer, we understand the importance of strength, weight reduction, and design flexibility. Our AS9100-certified processes and disciplined quality checks ensure each component meets your specifications for performance, durability, and compliance.

Common applications include:

- Seat backs, armrests, and surrounds

- Cabin and cockpit panels

- Lavatory partitions and housings

- Window shades and light bezels

- Ducting, trim panels, and system enclosures

Integrated Services for Aerospace Projects

We bring together design input, tooling for thermoforming, and finishing operations to simplify sourcing and shorten lead times. Projects are managed in-house, allowing tighter control over revision cycles and production readiness.

Explore how our custom thermoforming solutions support aerospace interiors from prototype to program launch.