Step 1: Understand the Challenge

We begin by gathering all key input. This includes your part requirements, production needs, material specs, and quality expectations. Our team identifies opportunities to streamline production, reduce waste, and keep the project on track.

We aim to:

- Align with your goals

- Improve material efficiency

- Recommend cost-effective approaches

- Identify ways to reduce lead time and bypass revalidation

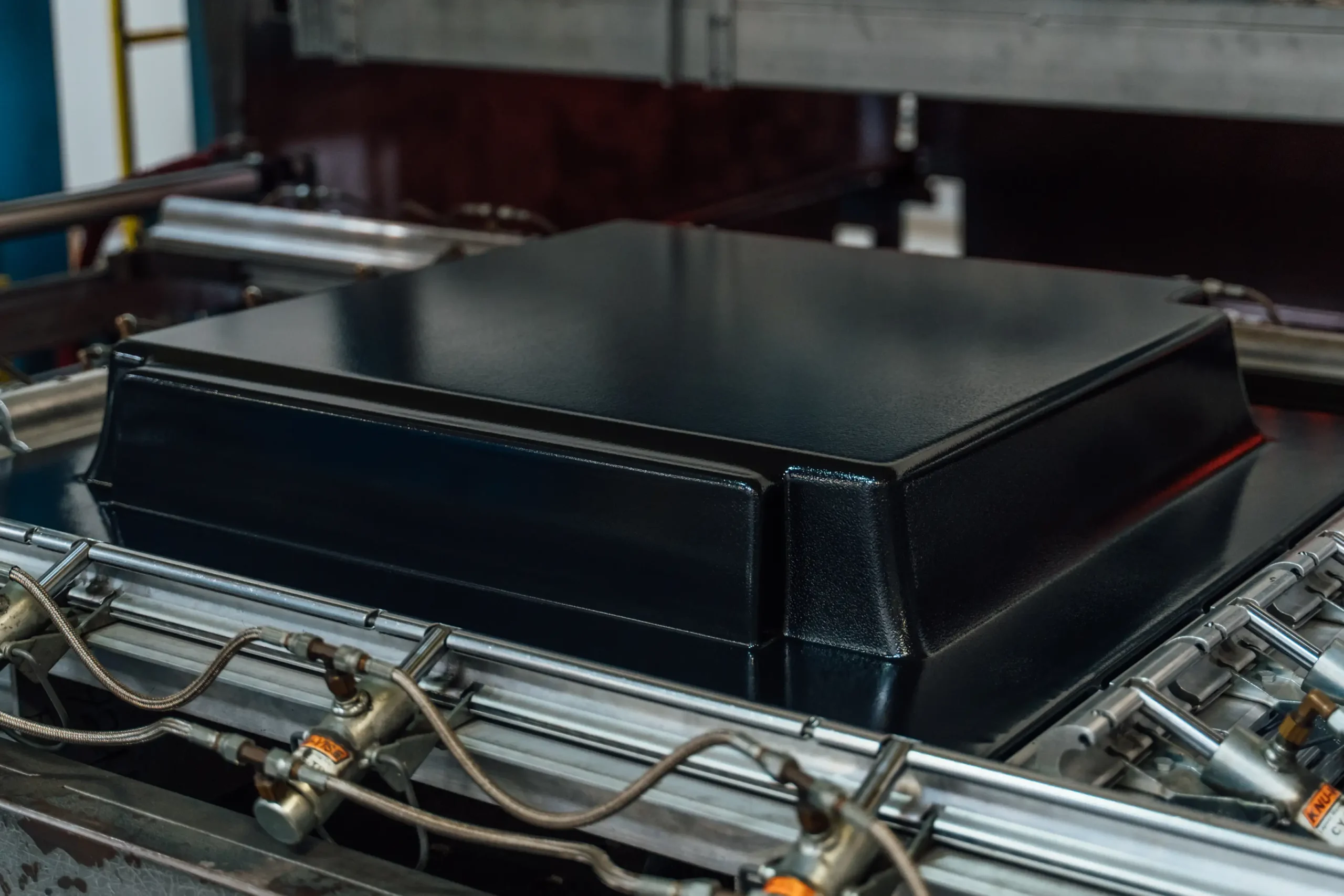

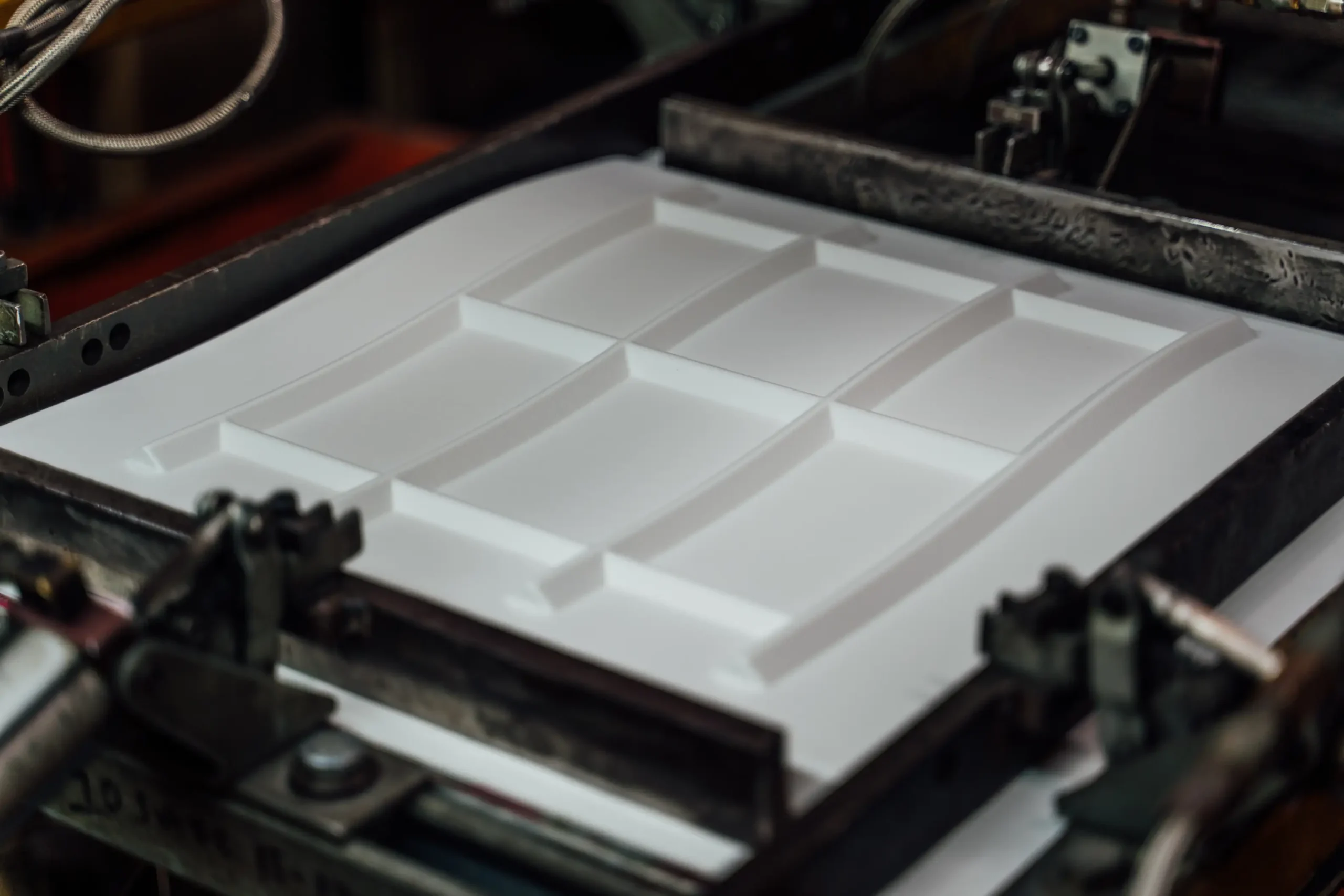

Step 3: Move to Production

Once approved, we transition to production with defined process controls and quality checkpoints. We identify inspection points, train operators, and validate all key parameters according to project requirements.

Production support includes:

- Equipment selection and setup

- In-process quality checks

- First Article Inspection

- Process validation (IQ, OQ, PQ, or PPAP, as needed)

- Safe handling and packaging protocols

Built Around Trust

We focus on getting it right the first time. Customers choose Tru-Form Plastics because we:

- Apply experience through a collaborative approach

- Accept complex, regulated applications

- Deliver logical, tool-driven solutions

- Help speed time to market through efficient validation

Explore how our process supports dependable results in medical thermoforming, aerospace plastic thermoforming, and other critical industries.