Understanding Medical Device Regulations

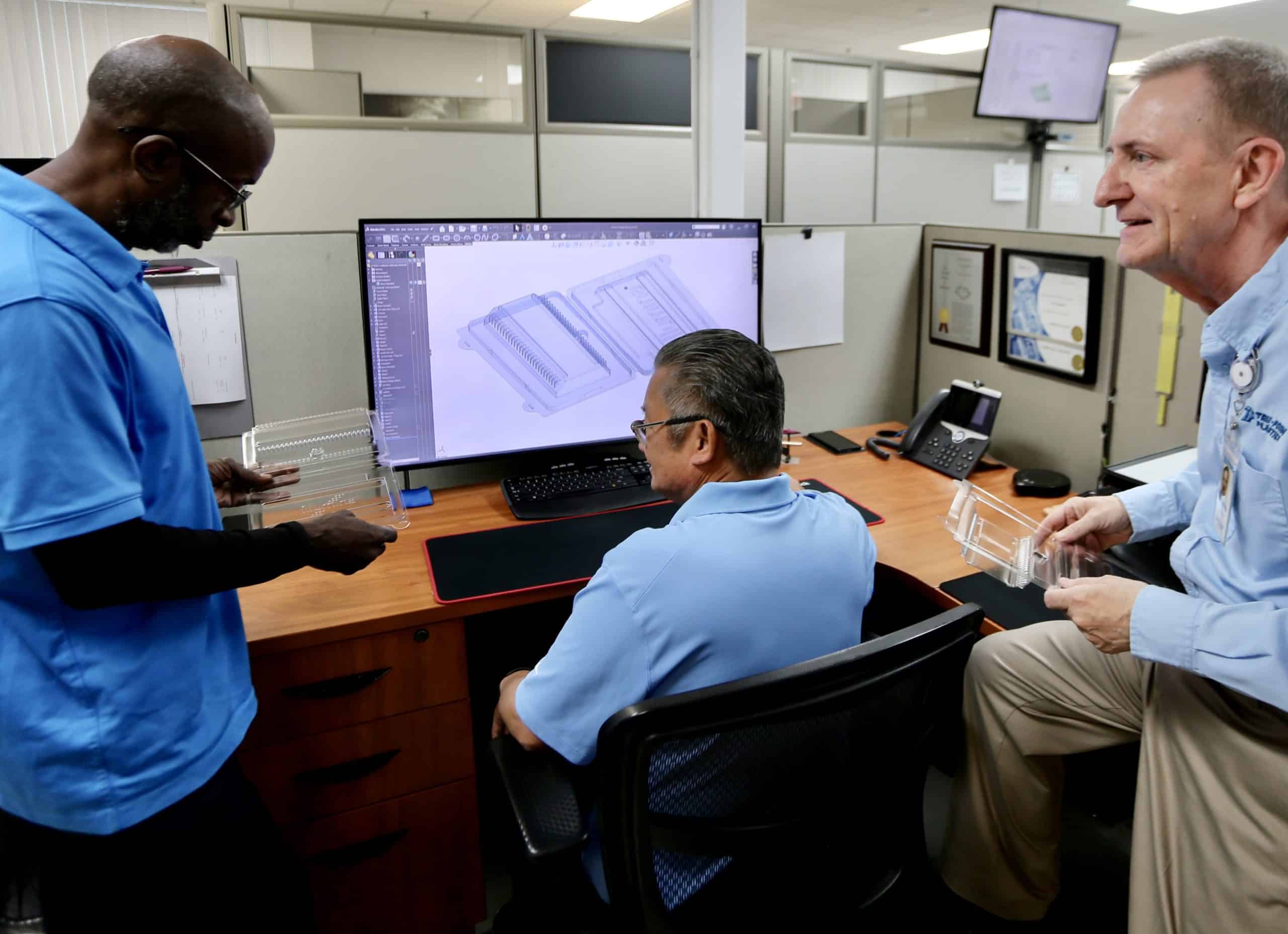

Regulatory compliance is a non-negotiable priority in the medical manufacturing industry, where strict adherence to quality and safety standards ensures patient well-being and protects businesses from liability. At Tru-Form Plastics, we recognize the importance of navigating complex regulatory landscapes and have built a reputation for excellence in compliance with medical device trays, medical packaging, and other critical solutions.

Certifications that Matter

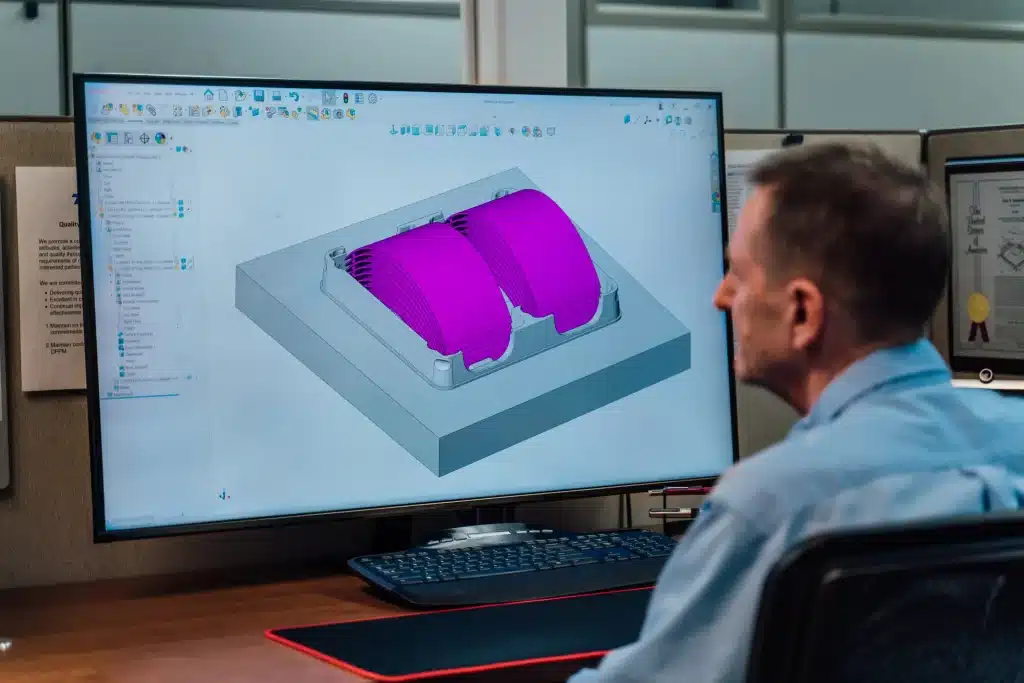

We hold AS9100 and ISO 9001:2015 certifications, reflecting our rigorous quality management system. These certifications enable us to provide custom thermoforming solutions and heavy and thin gauge thermoforming components that meet the most stringent medical packaging compliance requirements.

Expertise in Regulatory Standards

Our team’s extensive knowledge of medical manufacturing regulations allows us to meet and exceed expectations for thermoformed healthcare products and precision medical thermoforming. Whether you’re looking for regulatory expertise support for medical device packaging or medical device enclosure manufacturing, we ensure every step aligns with requirements from agencies like the FDA and ISO standards specific to medical product manufacturing.

Risk Mitigation Strategies

Tru-Form Plastics takes a proactive approach to managing compliance risks through:

- Comprehensive risk assessments to identify and address potential issues early in the production of custom medical packaging.

- First Article Inspections (FAI) and ongoing in-process quality checks to maintain compliance for thermoformed surgical trays and medical-grade plastic forming.

- Continuous improvement initiatives for enhanced product safety, durability, and reliability in our medical thermoforming.

By partnering with us, customers benefit from working with a California medical thermoforming who is a trusted collaborator in medical packaging validation. Our experience working with clients to assist with designs that meet stringent performance requirements ensures that your products meet the highest industry standards, from thin wall vacuum forming to lightweight medical enclosures.

When you need plastic packaging for medical applications, Tru-Form Plastics combines expertise in regulatory compliance with advanced capabilities to minimize risks and achieve excellence in high-precision medical packaging.