A Venus and Tru-Form Plastics Collaboration Case Study

Summary

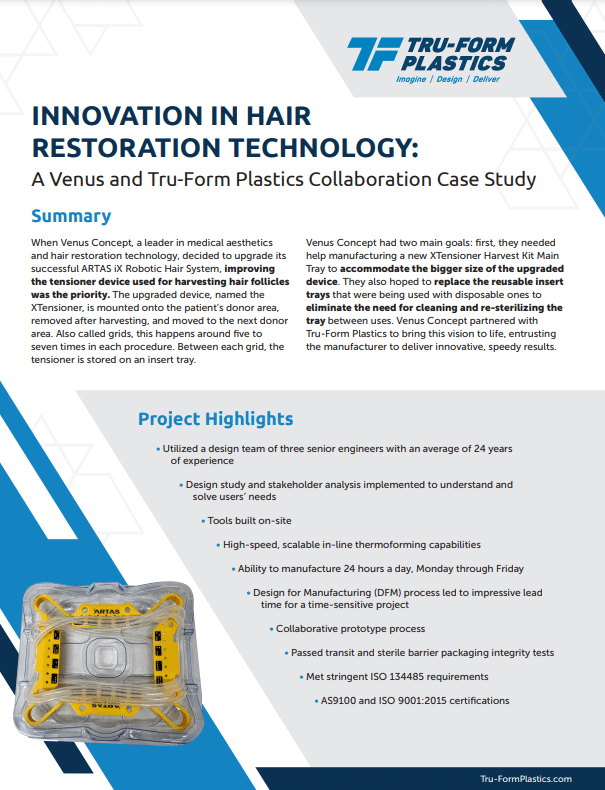

When Venus Concept, a leader in medical aesthetics and hair restoration technology, decided to upgrade its successful ARTAS iX Robotic Hair System, improving the tensioner device used for harvesting hair follicles was the priority. The upgraded device, named the Xtensioner, is mounted onto the patient’s donor area, removed after harvesting, and moved to the next donor area. Also called grids, this happens around five to seven times in each procedure. Between each grid, the tensioner is stored on an insert tray.

Venus Concept had two main goals: first, they needed help manufacturing a new XTensioner Harvest Kit Main Tray to accommodate the bigger size of the upgraded device. They also hoped to replace the reusable insert trays that were being used with disposable ones to eliminate the need for cleaning and re-sterilizing the tray between uses. Venus Concept partnered with Tru-Form Plastics to bring this vision to life, entrusting the manufacturer to deliver innovative, speedy results.

Project Highlights

- Utilized a design team of three senior engineers with an average of 24 years of experience

- Design study and stakeholder analysis implemented to understand and solve users’ needs

- Tools built on-site

- High-speed, scalable in-line thermoforming capabilities

- Ability to manufacture 24 hours a day, Monday through Friday

- Design for Manufacturing (DFM) process led to impressive lead time for a time-sensitive project

- Collaborative prototype process

- Passed transit and sterile barrier packaging integrity tests

- Met stringent ISO 134485 requirements

- AS9100 and ISO 9001:2015 certifications

The Design & Manufacturing Process

Before diving into the manufacturing process, Tru-Form Plastics started with a design study to understand the needs of everyone using this device, namely the nurses and doctors in the operating room.

A stakeholder analysis was then completed to solve the users’ requirements. This needs-based analysis helped Tru-Form Plastics better understand the product and brand, established a basis for creativity based on all parameters, product users, and stakeholders, and ultimately, helped get the product to market faster through the Design for Manufacturing process.

Tru-Form Plastics was then able to begin the design process, generating everything in-house with a design team of three senior engineers with an average tenure of 24 years. Tru-Form’s collaborative prototype process meant they worked with Venus Concept to produce multiple concept sketches and narrow them down to the best option. By avoiding subcontracting out concepts, sketches, prototypes, or any other part of the thermoforming process, Tru-Form Plastics maintained ownership of the project with Venus Concept from start to finish.

After designing the Main Tray and XTensioner Insert Tray, Tru-Form discovered a potential risk of the tray not sealing correctly. Two silicone tensioner straps were wrapped around the XTensioner and XTensioner Insert Tray, and during the sealing process, the straps were popping out – thus interfering with the seal. Tru-Form mitigated this risk by designing a third piece, the XTensioner Insert Tray Lid. After several changes and revisions, Tru-Form Plastics perfected the design, enabling the devices to perform as intended.

Results

Venus Concept successfully launched the new products in time thanks to Tru-Form Plastics’ high-speed thermoforming capabilities and the extra effort from the entire design and production team. The finished products met the requirements as mandated by ISO 13485. They also passed both transit testing and the sterile barrier packaging integrity test, ensuring they met the rigorous standards set by the medical industry. The collaboration was a success and resulted in a quality disposable harvest kit to use in conjunction with the ARTAS iX System for hair follicle harvesting and implantation procedures. The improvement of this trusted hair loss solution has led to many delighted customers who have increased their self-esteem and confidence thanks to the satisfactory results they’ve received from the device.

Want to learn more about how Tru-Form can help your bottom line? Contact us today to start a conversation.